Executive Summary

Lab-grown diamond manufacturing demands precision, uptime, and reliability. Traditional manual monitoring often leads to hidden equipment failures, causing costly delays. Dotcom’s S-Node, a plug-and-play IoT sensor system with AI-powered predictive analytics, enables real-time monitoring of critical assets—compressors, chillers, pumps—detecting anomalies before breakdowns occur. With secure wireless mesh networking and cloud-based ML analytics, S-Node saves up to 40 hours of downtime per month and protects revenue without requiring IT expertise.

The Challenge: Monitoring and Preventing Downtime in Diamond Production

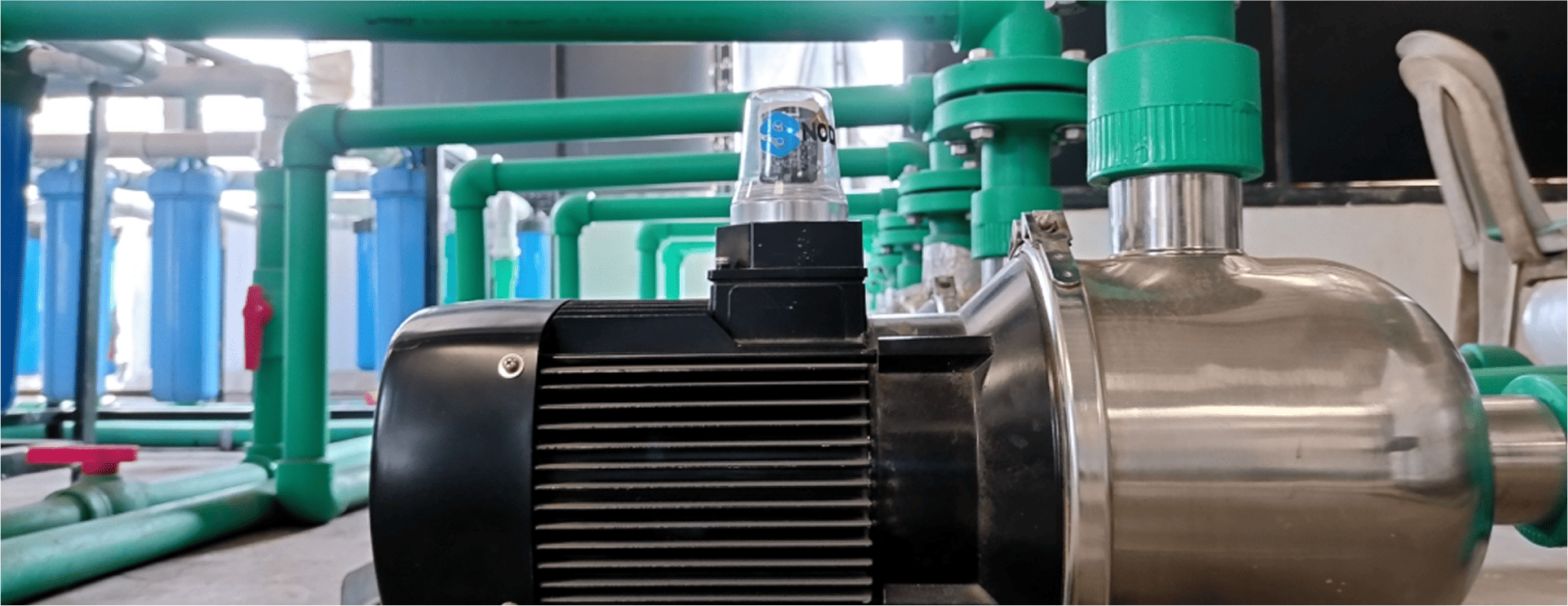

Lab-grown diamond factories in Surat use the CVD (Chemical Vapor Deposition) process—requiring precise control over vacuum chambers heated to 1,500°F and equipment like chillers, air compressors, and pumps. Key challenges include:

- Unpredictable Equipment Failures: Compressor and chiller breakdowns halt CVD processes, delaying export timelines.

- Manual Monitoring Limitations: Human checks fail to detect micro-faults like misalignment, cavitation, or unbalance.

- High Operational Risk: A single machine failure can compromise a full diamond growth cycle.

- Scalability Issues: Existing solutions require complex wiring and heavy technical dependency.

The Solution: Plug-and-Play Predictive Maintenance with S-Node

Dotcom’s S-Node – A battery-powered, magnet-mounted IoT sensor integrated with ML-driven predictive maintenance platform, built on a secure wireless mesh network for uninterrupted connectivity in metal-dense environments.

S-Node brings advanced predictive maintenance to diamond manufacturing with minimal installation effort and maximum reliability.

Core Components:

- S-Node Sensor measures triaxial vibration and temperature, while detecting misalignment, cavitation, unbalance, and bearing faults to ensure early identification of mechanical issues.

- Gateway Unit connects multiple S-Nodes through a secure mesh network and transmits the aggregated data to cloud-based analytics for further processing.

- Cloud Dashboard and Analytics provides real-time machine health monitoring and applies machine learning algorithms for accurate early fault prediction and actionable insights.

Key Takeaways

- Predictive maintenance is no longer optional—it’s a competitive advantage for diamond manufacturers.

- S-Node delivers industry-grade IoT with ML intelligence without IT dependency.

- Scalable, cost-effective, and future-ready solution for high-value manufacturing sectors.

Why Choose S-Node by Dotcom?

- Industry-Proven: 93% success rate across diamond producers in Surat.

- Non-Technical Deployment: No IT team required—maintenance staff can deploy.

- Revenue Protection: Minimizes risks of failed CVD batches and missed deadlines.

- Future-Ready: ML-driven insights with roadmap for AI-driven process optimization.

How It Works:

- Install Sensors: Attach magnet-based S-Nodes to compressors, chillers, or pumps (setup < 35 minutes).

- Data Acquisition: Continuous vibration & temperature data collection at high sampling rates.

- Wireless Mesh Communication: Data transmitted securely to the local gateway.

- Cloud Integration: Gateway pushes data via Ethernet/Wi-Fi to cloud analytics platform.

- ML-Driven Fault Detection: Predictive algorithms detect anomalies—unbalance, bearing wear, cavitation—before failure.

- Actionable Alerts: Dashboard triggers early warning alerts for maintenance teams.

Technical Architecture of S - Node:

Device Layer — S-Node (Sensor Node):

- The device uses a 32-bit ARM Cortex-M4 processor running at 64 MHz and supports NFC-A tags for easy provisioning.

- It includes an external 32 Mb NOR flash memory (Quad-SPI, 33 MHz, 8-WSON) for local buffering and firmware storage.

- Power is supplied by a 3.7 V, 500 mAh Li-Po battery, charged via USB 5 V/1 A, providing 2–3 years of battery life depending on the duty cycle.

- The enclosure is IP67-rated, UL94 V-0 flame retardant, and FCC/CE certified, with a compact design (Ø 60 mm × 70 mm), neodymium magnetic base, and tolerance for 2 m drop and 16 g continuous vibration.

- Connectivity is ensured via OpenThread-based secure mesh networking, using an integrated antenna with 1.5 dBi max gain.

- It operates reliably in extreme environments, handling –40 °C to 85 °C temperatures and up to 80% relative humidity.

- For security, it uses Mbed TLS cryptographic protocols, including AES-EBC, ECJ-PAKE, and SHA-256 for encryption and key management.

- The device integrates high-performance MEMS sensors, such as: > Triaxial vibration and IMU sensors (±2 g to ±16 g, gyroscope ±125 to ±2000 dps, kHz bandwidth). > Acoustic emission sensor (20 Hz–1 MHz, SNR 64 dB). > Magnetometer, IR thermal sensor (–20 °C to 200 °C), proximity, light, and UV sensors. > Environmental sensors for temperature, humidity, and pressure (260–1260 hPa). > Air quality sensors for IAQ, eCO₂, and bVOC levels, along with RPM monitoring.

Targets & Fault Modes (examples): imbalance, misalignment, looseness, pillow-block defects, friction, fluid noise, critical speed, impact.

Edge / Gateway Layer — S-Gateway (Border Router):

- Role: OpenThread border router + protocol conversion to MQTT.

- Host: Raspberry Pi running Eclipse Mosquitto (local broker), buffering & retry.

- Backhaul: Ethernet/Wi-Fi uplink to cloud; OTA provisioning for S-Nodes.

- Security: TLS 1.2 for MQTT to cloud; device identity pinned to X.509 certs.

Connectivity & IoT Core:

- Protocol: MQTT over TLS 1.2 from gateway to AWS IoT Core.

- Rules: IoT Rules route streams to S3 (raw), notifications, and invoke backends for inference.

Cloud Layer:

Data Handling:

1) Vibration Data Processing & Time-Domain Analysis

To ensure accurate fault detection, S-Node implements time-domain analysis of acceleration and speed data captured from capacitive MEMS sensors mounted on critical rotating equipment. During normal operation, these sensors record vibration along multiple axes (radial and circumferential) to detect deviations from baseline conditions.

Key statistical parameters such as Root Mean Square (RMS) and Maximum Peak Value are computed after digital pre-filtering to remove noise and extract meaningful trends. These values are then compared against runtime thresholds, which are derived either from equipment manufacturer recommendations or user-defined limits during the learning phase.

If RMS or peak vibration values approach these thresholds, the system generates real-time alarms or warnings, enabling proactive intervention before critical failure occurs. This approach provides actionable insights even before frequency-domain transformations, ensuring faster anomaly detection.

2) Frequency-Domain Analysis & Advanced Signal Processing

While time-domain analysis provides real-time anomaly detection, frequency-domain analysis offers deeper insights into machine health by decomposing vibration signals into their frequency components.

This is achieved through an optimized Fast Fourier Transform (FFT) pipeline, which breaks down raw accelerometer data into harmonic frequencies, helping identify defects like unbalance, misalignment, and bearing faults.

The FFT process follows key steps:

- Data Acquisition and Pre-Filtering: MEMS accelerometer data is filtered and normalized to remove noise.

- Windowing: A Hanning window is applied to mitigate spectral leakage from discontinuous signals.

- FFT Evaluation and Averaging: FFT is computed for multiple overlapping data blocks, and averaged to minimize noise and ensure stable frequency signatures.

- Feature Extraction: Parameters such as peak amplitude and harmonic frequencies are extracted for condition-based monitoring.

3) Embedded Processing with STM32 MCU

The STM32 ARM® Cortex®-M4 microcontroller with integrated FPU executes real-time signal processing, leveraging the CMSIS DSP library for filtering, windowing, and FFT computation. Critical functions include:

- arm_mult_f32 for applying window functions

- arm_rfft_fast_f32 and arm_cmplx_mag_f32 for FFT evaluation

- arm_max_f32 for extracting maximum FFT peak and frequency

To ensure real-time performance, the system employs a dual-buffer strategy with DMA:

- A circular buffer collects incoming accelerometer data without loss.

- A secondary buffer processes FFT blocks concurrently.

- This approach supports FFT averaging and parallel operations without interrupting data acquisition.

- Ingest: Real-time telemetry via AWS IoT → S3 data lake (parquet/JSON) with partitioning.

- Pre-processing: Denoising, resampling, normalization; feature extraction (RMS, kurtosis, crest factor, spectral peaks, envelope).

- Cold/Hot Storage: S3 (raw/processed); MySQL for metadata, assets, thresholds, events.

ML / Analytics Engine:

- Services: EC2 (Python/Flask) microservice for live inferencing, auto-training, threshold learning.

- Models: > Unsupervised anomaly scoring (e.g., isolation forest/autoencoder) on vibration & acoustic features. > Fault classifiers for unbalance/misalignment/bearing wear/cavitation. > Remaining-useful-life (RUL) trend via health index smoothing.

- Pipelines: Scheduled retraining with drift checks; model/feature versioning; A/B model rollout.

API Services:

- REST APIs: Secure JWT-backed endpoints for device mgmt, telemetry query, alert ack, and inference.

- AuthN/Z: AWS Cognito or IAM-backed credentials; per-tenant policies; expiring presigned S3 links.

Observability & Ops:

- Monitoring: Metrics/logs/alerts for gateway uptime, node battery, packet loss, ML latency; OTA status.

- Device Management: Fleet registry, shadow states, firmware OTA (FOTA), key rotation.

Application Layer:

Web Frontend (Operations Portal):

- Functions: Asset views, trend charts, order tracking of alerts, threshold tuning, rule authoring.

- Data Access: Reads/writes via REST; queries MySQL for assets/events; pulls plots from S3.

Security Summary:

- The device layer implements Mbed TLS cryptography, supports signed firmware, and recommends secure boot for enhanced integrity and trust.

- The transport layer uses MQTT over TLS 1.2, combined with certificate-based authentication and rule-scoped IAM policies for secure communication.

- The data layer ensures protection with S3 server-side encryption managed by AWS KMS keys, avoids storing personally identifiable information (PII), and enforces row-level tenancy in MySQL for data isolation.

Application & Use Cases:

Lab-Grown Diamond Manufacturing:

- Application: Monitor CVD chambers, compressors, chillers, and vacuum pumps.

- Use Case: Detect misalignment, cavitation, or vibration anomalies in compressors before they impact the diamond growth cycle.

- Benefit: Avoids failed diamond batches, reduces downtime by up to 40 hours/month, and ensures timely exports.

Oil & Gas Industry:

- Application: Monitor rotating equipment such as pumps, compressors, and turbines in offshore/onshore rigs.

- Use Case: Detects bearing wear or critical speed vibrations in crude oil pumps before catastrophic failure.

- Benefit: Prevents unplanned shutdowns, ensures safety compliance, and minimizes production losses.

Cement Manufacturing:

- Application: Monitor bearings, motors, and gearboxes across heavy-duty kilns and mixers.

- Use Case: Early detection of imbalance in rotary kilns to prevent expensive mechanical failure.

- Benefit: Improves reliability and reduces maintenance costs in continuous-process plants.

Chemical & Pharmaceutical Plants:

- Application: Monitor mixers, centrifuges, and air handling units (AHUs).

- Use Case: Predict maintenance for HVAC fans and air compressors critical for sterile conditions.

- Benefit: Ensures compliance with regulatory standards (GMP) and avoids production loss due to contamination risk.

Paper & Pulp Industry:

- Application: Monitor rollers, bearings, and motors exposed to heat and humidity.

- Use Case: Detects excessive friction or heat in rollers to prevent machine fires.

- Benefit: Increases machine safety and process reliability in harsh environments.

Mining & Metals (Steel Mills):

- Application: Monitor gearboxes, turbines, and heavy-duty motors in extreme conditions.

- Use Case: Predict gearbox failures in mining conveyors or rolling mills.

- Benefit: Reduces downtime in high-load, high-temperature conditions and improves worker safety.

HVAC & Facility Management:

- Application: Monitor AHUs, fans, and chillers in large commercial buildings and data centers.

- Use Case: Detect early signs of bearing failure in fans to maintain cooling efficiency.

- Benefit: Energy savings and uninterrupted operation in mission-critical environments.

Power Generation:

- Application: Monitor turbines, alternators, and pumps in thermal, hydro, or wind power plants.

- Use Case: Detects imbalance or bearing degradation in wind turbine gearboxes.

- Benefit: Avoid catastrophic failure, extend asset life, and maintain grid reliability.

Food & Beverage Industry:

- Application: Monitor motors and conveyors in automated processing plants.

- Use Case: Predict maintenance of bottling line motors to prevent downtime during peak production.

- Benefit: Reduces unexpected line stoppage and improves overall throughput.

Automotive & Heavy Manufacturing:

- Application: Monitor robotic arms, presses, and assembly-line motors.

- Use Case: Detects resonance or alignment issues in servo motors before production loss.

- Benefit: Ensures consistent product quality and reduces unplanned maintenance.

Results & Benefits:

Key Features:

- Plug-and-Play Installation: Magnetic mount, no rewiring required.

- Secure Wireless Mesh: Resilient connectivity in metal-heavy environments.

- ML-Based Predictive Analytics: Advanced fault detection for vibration anomalies.

- Real-Time Dashboard: Instant machine health visibility.

- Ultra-Low Power: Extended battery life for remote installations.

Future Scope:

- AI Optimization for Energy Efficiency: Predictive analytics extended to power consumption.

- Integration with ERP/MES: Automated maintenance scheduling and reporting.

- Edge AI Processing: On-device intelligence for low-latency fault prediction.

“S-Node: AI-Driven IoT Solution for Zero-Downtime Diamond Production”